категории

последний блог

Каков процесс индивидуальной настройки спектрометров перед отправкой?

Jan 13 , 2026Каков процесс индивидуальной настройки спектрометров перед отправкой?

Спектрометры широко используются для анализа различных металлов и сплавов, позволяя быстро определять содержание конкретных элементов. Они применяются в двух основных отраслях промышленности: контроль материалов перед загрузкой печей и контроль сырья.

Однако, исходя из различных потребностей разных клиентов, аппаратная структура спектрометра, программные функции и параметры должны быть специально скорректированы для достижения требуемой точности.

Стандартный процесс настройки

1. Убедитесь в исправности прибора.

1.1. Экологическая проверка

Потому что спектрометры Приборы, в которых используются встроенные ПЗС или КМОП-детекторы, предъявляют чрезвычайно высокие требования к условиям окружающей среды. Для обеспечения нормальной работы прибор должен быть размещен на достаточно открытом пространстве, вдали от печей с высокой и низкой частотой нагрева и вибраций;

Кроме того, температура должна находиться в диапазоне 34±0,5 градусов Цельсия, влажность ниже 75%, а уровень вакуума ниже 20.

1.2. Проверка приборов

Первый шаг: Очистка искровой платформы и линзы. Перед возбуждением образца необходимо очистить искровой столик и линзы, чтобы обеспечить полное прохождение света через линзы и его проекцию на дифракционную решетку, что позволит точно проанализировать содержание элементов.

Второй этап: промывка аргоном. После очистки первым шагом является промывка аргоном для полного заполнения искрового разрядника и удаления воздуха, чтобы предотвратить поглощение света и неточные результаты.

Третий шаг: Проверка затвора Основная функция затвора спектрометра заключается в точном контроле времени, необходимого детектору для приема световых сигналов, что защищает детектор и обеспечивает точность данных. Проще говоря, затвор перемещается вверх и вниз на разных этапах, блокируя или пропуская свет к линзе, тем самым обеспечивая точность данных. Поэтому правильное перемещение затвора имеет решающее значение.

Четвертый шаг: разминка оборудования. Если прибор долгое время не подвергался возбуждению, начальной энергии возбуждения недостаточно для полного возбуждения образца. Поэтому перед формальным возбуждением образцы отходов необходимо непрерывно возбуждать, чтобы прогреть прибор и увеличить энергию возбуждения.

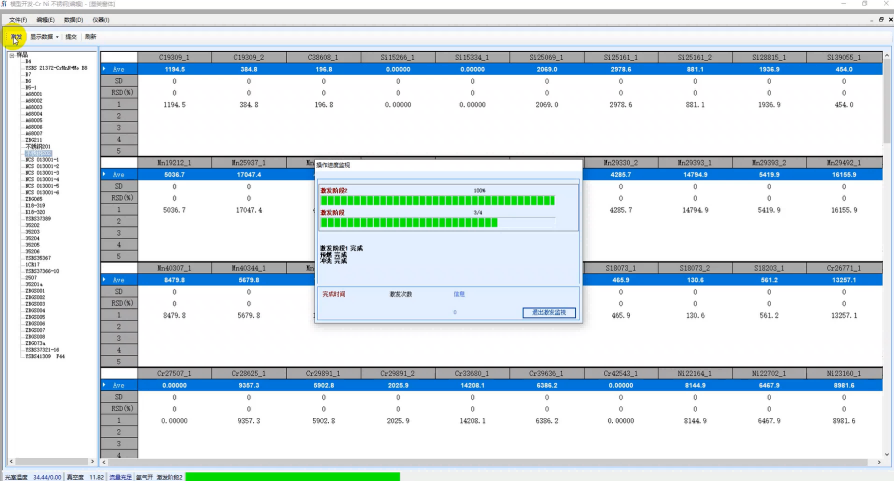

Пятый шаг: Тест на помехи Цель интерференционного теста — обнаружение наличия или отсутствия сигнала, проверка воспроизводимости и определение качества эффекта возбуждения. Путем многократного возбуждения одной и той же точки определяется, совпадают ли кривые.

2. Калибровка

2.1. Операция:

Путем возбуждения нескольких стандартных образцов спектральные линии отображаются в программном обеспечении. Пиковые значения различных спектральных линий сопоставляются с линиями элементов на определенных длинах волн, что позволяет выполнить калибровку.

2.2. Цель:

Основная цель калибровка спектрометра Цель состоит в устранении ошибок в работе приборной системы, установлении точного соответствия между регистрируемым сигналом и истинными свойствами вещества, а также обеспечении точности, воспроизводимости и прослеживаемости результатов обнаружения.

В частности, это отражается в следующих аспектах: Точность калибровочной длины волны: Коррекция отклонения между пикселями детектора и фактической длиной волны, обеспечение точной идентификации характерных спектральных линий веществ при качественном анализе и предотвращение неправильной классификации типов элементов.

3. Подгонка кривых и построение модели

3.1. Операция:

С помощью программного обеспечения прибора выполняется линейная или нелинейная аппроксимация, где по оси абсцисс откладывается содержание элементов в стандартном образце, а по оси ординат — интенсивность соответствующей характеристической спектральной линии.

Для устранения помех спектральных линий от сосуществующих элементов и матричных эффектов вводятся коэффициенты матричной коррекции и коэффициенты коррекции интерференции, что улучшает корреляцию кривых.

3.2. Цель:

Калибровка количественной зависимости между интенсивностью и содержанием: создание надежной модели «спектральная интенсивность - элементный состав» для устранения влияния различий в отклике пикселей, колебаний источника света и матричных эффектов, обеспечивающей соответствие результатов количественного анализа истинному содержанию.

Обеспечение достоверности данных: Калибровка гарантирует соответствие данных, полученных с помощью прибора, отраслевым стандартам (например, ISO 17025), обеспечивая сопоставимость и прослеживаемость результатов, полученных в разное время и с использованием разных приборов, тестирующих один и тот же образец.

4. Проверка и оптимизация кривых

4.1. Операция:

Во-первых, стандартизация осуществляется путем сравнения высоких и низких стандартов. Стандартизированные процедуры калибровки приборов, обработки образцов и настройки параметров позволяют избежать ошибок, вызванных различиями в работе, обеспечивая согласованные результаты обнаружения для одного и того же образца в разное время и на разных приборах, что исключает ошибочные выводы.

Во-вторых, тестирование проводится с использованием 1-2 контрольных образцов с промежуточными концентрациями. Сравнивается отклонение между обнаруженным значением и стандартным значением; отклонение должно находиться в допустимом диапазоне. Если отклонение слишком велико, необходимо повторно оптимизировать параметры или добавить дополнительные стандартные образцы, а также скорректировать модель подгонки до тех пор, пока не будет достигнуто соответствие стандарту.

4.2. Цель:

Выявление недостатков калибровки В ходе контроля качества образцов необходимо проверить отклонение аппроксимации и диапазон линейности кривых, чтобы выявить такие проблемы, как неправильный выбор стандартных образцов и необоснованные настройки параметров, предотвращая использование ошибочных кривых в реальных испытаниях.

Устраните факторы помех. В процессе оптимизации вводятся коэффициенты коррекции матрицы и коррекции интерференционных элементов для компенсации влияния матричных эффектов образца и перекрытия спектральных линий, что делает соответствие «интенсивность света — содержание света» более согласованным с реальным сценарием тестирования образца.

Обеспечьте согласованность данных. Регулярная проверка и оптимизация позволяют компенсировать влияние дрейфа прибора и изменений окружающей среды, обеспечивая повторяемость результатов испытаний в разных партиях и соответствие строгим требованиям к точности данных при контроле качества металлических материалов и приемке готовой продукции.

5. Сохранение и применение кривых:

Сохраняйте калибровочные кривые по имени (с указанием типа стандартного образца, элемента и времени создания) для быстрого доступа при последующем тестировании аналогичных образцов.

Регулярно проверяйте стабильность кривой с помощью контрольных образцов; если дрейф превышает пороговое значение, выполните повторную калибровку.

Пожалуйста, свяжитесь с нами для получения дополнительной информации или более подробных сведений!

Тел.: +86-183-5283 6805

Электронная почта: sales@jinyibo.com